The top ten most frequently asked questions about connectors by customers

- Share

- Issue Time

- Sep 17,2025

Summary

When engineers, buyers, and technicians search for connectors, they often encounter the same challenges: choosing the right type, ensuring durability, verifying certifications, and finding a trustworthy M16 circular connector supplier.

When engineers, buyers, and technicians search for connectors, they often encounter the same challenges: choosing the right type, ensuring durability, verifying certifications, and finding a trustworthy M16 circular connector supplier.

At Connoder (About Us), we’ve worked with global customers across industrial automation, robotics, and transportation. Drawing from the most frequently asked questions in the connector industry, here we answer the Top 10 FAQs about connectors, while showing how Connoder provides solutions tailored to your needs.

1. What is a connector and why does it matter?

Connectors ensure secure transmission of power and signals. Without reliable connectors, even the best equipment risks downtime. 👉 Connoder specializes in M16 circular connectors, chosen for their compact size and rugged build, perfect for demanding industrial applications.

2. Why choose an M16 circular connector?

Compact form factor

Multiple pin configurations

IP67/IP68 waterproof options

Easy assembly and panel mounting

✔ At Connoder, our M16 series is trusted by manufacturers worldwide for both performance and durability.

3. How do I know if a connector is waterproof?

Check the IP rating:

- IP67 = temporary water immersion

- IP68 = extended submersion protection

Connoder’s M16 circular connectors undergo strict IP testing, ensuring consistent performance in outdoor and industrial environments.

4. What are connectors made from?

Common materials include:

- Metal housings (brass, stainless steel) for durability

- Plastic housings for lightweight use

- Gold/nickel-plated contacts for conductivity

👉 Connoder uses high-grade materials and plating to guarantee long-term reliability.

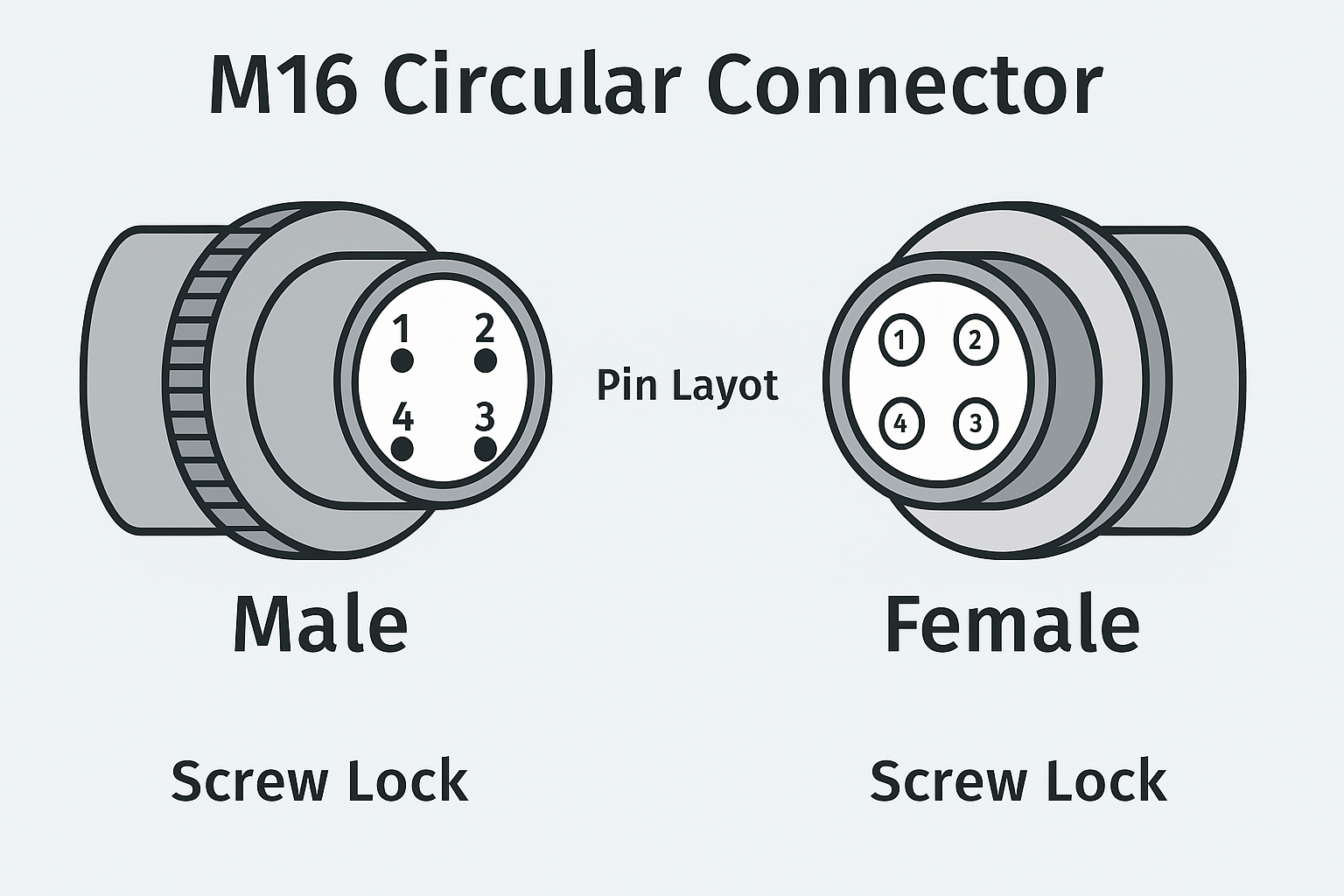

5. How do male and female connectors work?

Male plug (pins) connects into female socket (receptacles). Connoder’s precision-engineered mating systems ensure secure locking and reduced wear during repeated use.

Pin layout of M16 circular connector

M16 Circular Connector International Certification

Application scenarios of M16 circular connectors

6. What pin configurations are available for M16 connectors?

- 2–4 pins: Power supply

- 5–8 pins: Power + signal

- 12+ pins: Complex control

✔ Connoder offers standard and customized pin layouts, supporting both off-the-shelf and OEM requirements.

7. Are all M16 connectors from different suppliers compatible?

Not necessarily. While “M16” defines size, locking systems and layouts can differ. Connoder ensures full DIN and IEC compliance, providing connectors that integrate smoothly across brands.

8. What certifications should I expect from a supplier?

ISO 9001 (Quality)

RoHS & REACH (Environmental)

UL / CE (Safety)

Connoder is a certified M16 circular connector supplier, committed to international standards.

9. What common issues do customers face with connectors?

Misleading datasheets

Poor sealing performance

Long lead times

Lack of technical support

👉 Connoder addresses these concerns with transparent datasheets, rigorous QC testing, global logistics, and 24/7 technical support.

10. How do I choose the right connector supplier?

Proven experience in the connector industry

Certified, tested products

Customization and flexible MOQ

Global delivery

Responsive customer support

✔ Connoder combines decades of expertise, certified production, and a global customer base. Visit our About Us page to learn more about our mission and capabilities.

Conclusion & Call to Action

Choosing the right connector starts with the right partner. At Connoder, we don’t just supply connectors — we provide complete connection solutions that empower industries to perform reliably.

📩 Ready to source from a trusted M16 Circular Connector Supplier? Contact Connoder today for product catalogs, samples, or a custom quote.

How do I choose the right connector for my industrial equipment (e.g., on-site sensors, control cabinets)?

Focus on three core factors: first, environmental adaptability – select connectors with IP67/IP68 rating if the site has dust, moisture, or vibration (e.g., M12 circular connectors for sensors); second, electrical performance – match current/voltage requirements (e.g., high-current scenarios need silver-plated connectors, while high-frequency signal transmission needs gold-plated ones); third, installation space – choose miniaturized or high-density connectors (e.g., board-to-board connectors) if the equipment interior is compact. Avoid over-specifying (e.g., using aerospace-grade connectors for ordinary industrial control) to balance performance and cost.

My existing connector is from Brand A, can I replace it with a compatible one from Brand B to save cost?

It depends on "mechanical and electrical compatibility": first, check physical dimensions (e.g., interface diameter, pin spacing, fastening structure) – ensure they are consistent with Brand A’s specifications (e.g., M16 connectors must have the same thread size); second, verify electrical parameters (e.g., contact resistance, insulation resistance, rated current) – they should meet or exceed the original standard; third, confirm coding compatibility (for anti-misplug connectors) – if Brand A uses A-coding, Brand B’s replacement must also be A-coding. It’s recommended to test 2-3 samples first (e.g., conduct continuity and vibration tests) before batch replacement.

Why does my connector fail after only a few months of use, even though it’s supposed to have a 5-year service life?

Common causes include: ① improper installation (e.g., excessive torque leading to shell cracking, or insufficient insertion force causing loose contact); ② environmental damage (e.g., unprotected use in high-humidity environments leading to terminal corrosion, or dust accumulation blocking the interface); ③ overload operation (e.g., using a 5A connector for 10A current, causing overheating and 镀层 melting). To extend life, follow the manual for installation (control torque/insertion force), add protective measures (e.g., dust caps for unused connectors), and avoid exceeding rated parameters.

How do I troubleshoot "intermittent contact" issues with my connector (e.g., the device occasionally powers off or signals drop)?

Follow this step-by-step process: ① visual inspection – check if the connector shell is cracked, pins are bent, or there’s rust/oxidation on the contacts; ② mechanical check – gently wiggle the connector and wire harness – if the issue recurs, it may be loose fastening or poor crimping; ③ electrical testing – use a multimeter to measure contact resistance (normal value: <50mΩ) – if it’s too high, clean the contacts with alcohol (avoid abrasive materials) or replace the connector; ④ environmental check – if used outdoors, verify if the seal is damaged (e.g., O-ring falling off) and replace the seal if needed.

M16 6 Pin Circular Connector A-Code Interface, Waterproof Connector Receptacle Cable, Straight, Front-Locking, Unshielded

M16 6 Pin Circular Connector assemblies are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems.

M16 6 Pin Circular Connector are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems. M16 Circular Connector are available in quick-lock wiring assembly types with IP67 protection and a vibration-resistant screw design.

M16 6 Pin Circular Connector are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems. M16 Sensor connector are available in quick-lock wiring assembly types with IP67 protection and a vibration-resistant screw design.