The application of M16 circular connectors in intelligent manufacturing equipment

- Share

- Issue Time

- Oct 14,2025

Summary

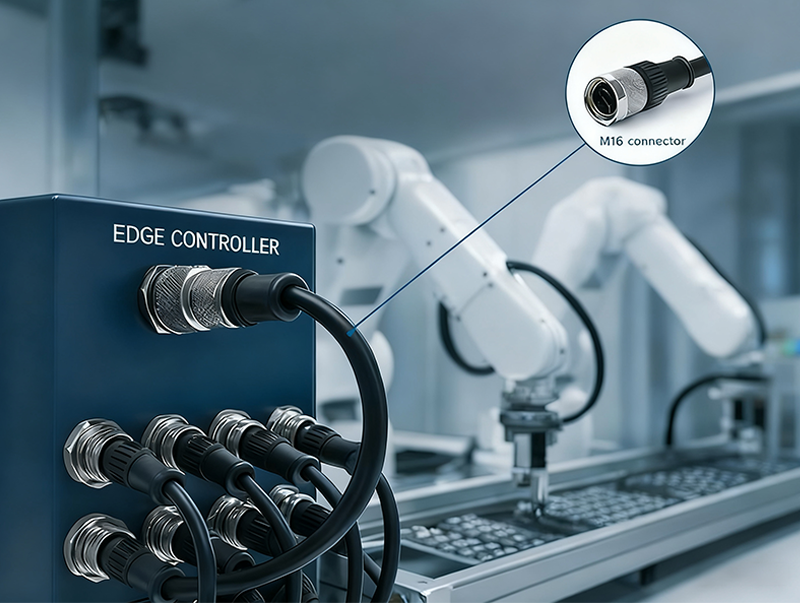

In today’s Industry 4.0 era, intelligent manufacturing equipment—such as robots, sensor networks, smart conveyors, and automated inspection systems—requires reliable, compact, and versatile connector solutions. Among these, M16 circular connectors have become a preferred choice due to their balance of size, multi-pin capability, and robust performance.

Introduction

In today’s Industry 4.0 era, intelligent manufacturing equipment—such as robots, sensor networks, smart conveyors, and automated inspection systems—requires reliable, compact, and versatile connector solutions. Among these, M16 circular connectors have become a preferred choice due to their balance of size, multi-pin capability, and robust performance.

Common Connector Types for High-Speed Transmission

Compact Design with Multi-Pin Flexibility

M16 connectors provide more pins than smaller formats like M8 or M12 while staying compact—ideal for dense control systems. They support up to 24 contacts, allowing combined power and signal transmission in one interface.

Environmental Resilience & Sealing

With IP67 to IP69K protection, M16 connectors are resistant to dust, oil, moisture, and vibration, making them perfect for harsh manufacturing environments and outdoor automation.

Mechanical & EMI Strength

Featuring metal shells, screw or bayonet locks, and 360° shielding, M16 connectors ensure excellent electrical stability even under vibration and EMI interference.

Hybrid & High-Speed Data Options

Modern M16 designs support hybrid (signal + power) layouts and high-speed data transmission up to 10 Gbps, enabling future-ready Industry 4.0 communication.