OEM vs ODM: Which Model is More Suitable for M16 Circular Connector Procurement?

- Share

- Issue Time

- Oct 8,2025

Summary

When sourcing industrial connectors, selecting the right M16 circular connector supplier is just as important as deciding on the appropriate procurement model. Buyers today often face the choice between OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer).

OEM vs ODM: Which Model is More Suitable for M16 Circular Connector Procurement?

Introduction

When sourcing industrial connectors, selecting the right M16 circular connector supplier is just as important as deciding on the appropriate procurement model. Buyers today often face the choice between OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer).

At Connoder, we understand that every procurement decision is strategic. With years of expertise in connector manufacturing and global distribution, we provide tailored OEM and ODM solutions to ensure our clients get the most reliable M16 circular connectors for their applications.

M16 Circular Connectors

Rugged, compact and versatile — ideal when you need mixed power & signal plus environmental protection.

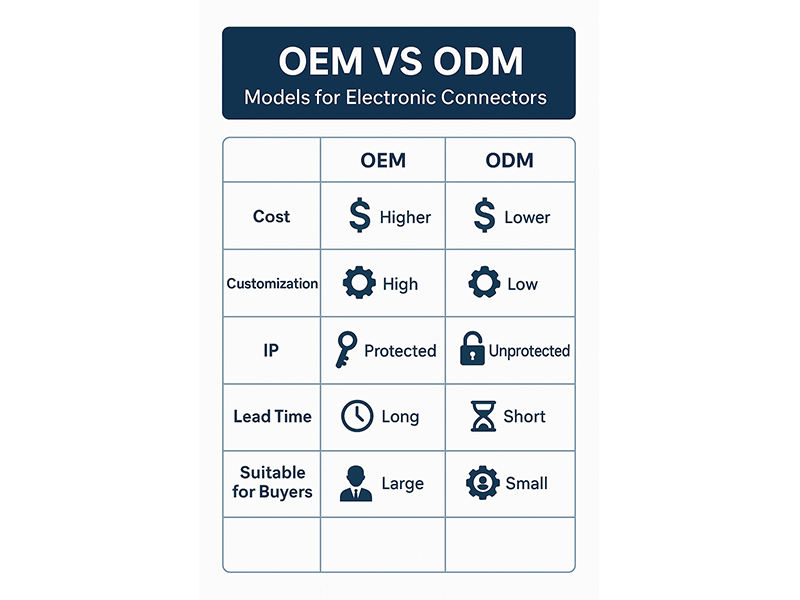

OEM vs ODM: Understanding the Basics

OEM (Original Equipment Manufacturer)

Buyers provide full product design and technical specifications.

Supplier manufactures strictly according to the buyer’s drawings.

Advantages: IP protection, high customization, unique product differentiation.

Challenges: higher tooling costs, longer lead times, higher minimum order quantities (MOQ).

ODM (Original Design Manufacturer)

Supplier provides pre-engineered products that can be slightly customized or rebranded.

Faster time-to-market and lower initial investment.

Advantages: cost-efficient, flexible MOQ, quicker delivery.

Challenges: less design control, limited customization options.

Key Factors in Choosing the Right Model for M16 Connectors

Customization Needs: OEM allows full specification; ODM offers faster availability.

Intellectual Property: OEM ensures design ownership; ODM retains core design.

Cost and Lead Time: OEM suits long-term projects; ODM is ideal for startups.

MOQ and Flexibility: OEM = larger batches; ODM = smaller runs.

Quality and Compliance: Both require standards; Connoder ensures IP67/IP68 and RoHS compliance.

OEM and ODM product models of M16 circular connectors

When choosing an M16 circular connector model, customers need to define their requirements. Whether it is an OEM or ODM model, they should pay attention to the manufacturer's certifications (such as UL, CE, RoHS) and after - sales service capabilities. This ensures that the product meets industry compliance requirements and also guarantees subsequent maintenance and replacement needs.

OEM vs ODM: Which Should You Choose?

Choose ODM if you need fast delivery, cost-efficient solutions, or smaller volumes.

Choose OEM if your project requires unique pin configurations, exclusive designs, or long-term supply chain security.

Many companies adopt a hybrid strategy: starting with ODM, then moving to OEM for scaling and IP ownership.

M16 circular connector moisture-proof test

The moisture - proof performance of M16 circular connectors does not solely rely on test verification. Instead, it is closely related to product design and material selection, with testing serving as the final check of these designs.

Why Connoder Is the Right Partner

Comprehensive OEM & ODM Services: From consultation to production.

Technical Expertise: High-performance connectors for automation, robotics, and telecom.

Certified Quality: IP67/IP68, RoHS & REACH compliance, rigorous testing.

Flexible Supply Chain: Support for prototypes and mass production.

Global Reach: Efficient logistics and client support worldwide.

M16 circular connector assembly

A standardized assembly process not only ensures the basic functions of the connector but also prevents issues such as signal interruption, short - circuit, or protection failure caused by improper assembly. Therefore, it is necessary to follow standardized procedures and strict quality control standards.

FAQ

Q1: What’s the MOQ difference between OEM and ODM for M16 connectors?

A: ODM supports lower quantities, while OEM typically requires larger batches due to tooling investment.

Q2: Can Connoder provide samples?

A: Yes, we provide ODM samples and OEM prototypes for client verification.

Q3: How long is the typical lead time?

A: ODM: 2–4 weeks; OEM: 6–12 weeks depending on customization.

Q4: Are Connoder’s connectors certified?

A: Yes, all products comply with RoHS, REACH, and IP67/IP68 standards.

Conclusion

Choosing between OEM and ODM depends on your project’s goals, budget, and timeline. The right M16 circular connector supplier makes all the difference.

At Connoder, we deliver both OEM and ODM services with the same commitment to quality, durability, and customer success.

👉 Contact us today to discuss your M16 connector procurement strategy and request a quote or sample.

What is the main difference between OEM and ODM when sourcing M16 circular connectors?

OEM (Original Equipment Manufacturer) means the supplier manufactures based on your unique design and specifications, giving you full IP ownership and customization. ODM (Original Design Manufacturer) provides pre-engineered connectors that can be rebranded or slightly customized, offering faster delivery and lower upfront costs.

Which model—OEM or ODM—is better for small batch M16 connector procurement?

ODM is more suitable for small batch orders because it supports lower MOQs (minimum order quantities) and shorter lead times, making it ideal for startups or pilot projects.

Can Connoder provide both OEM and ODM services for M16 circular connectors?

Yes. Connoder offers both OEM and ODM services. We can supply ready-to-use ODM connectors for fast delivery and also support fully customized OEM solutions for clients needing exclusive designs and long-term scalability.

How does choosing the right M16 circular connector supplier impact procurement success?

The right supplier ensures product reliability, compliance with international standards (IP67/IP68, RoHS, REACH), flexible delivery options, and professional technical support—factors that directly influence project success and cost efficiency.

M16 6 Pin Circular Connector A-Code Interface, Waterproof Connector Receptacle Cable, Straight, Front-Locking, Unshielded

M16 6 Pin Circular Connector assemblies are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems.

M16 6 Pin Circular Connector are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems. M16 Circular Connector are available in quick-lock wiring assembly types with IP67 protection and a vibration-resistant screw design.

M16 6 Pin Circular Connector are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems. M16 Sensor connector are available in quick-lock wiring assembly types with IP67 protection and a vibration-resistant screw design.