Common Causes of Connector Failures and Their Solutions

- Share

- Issue Time

- Sep 15,2025

Summary

Installing M16 circular connectors correctly is essential to guarantee long-term reliability and safety in demanding applications. Field studies and technical research (Arrow, Keyence, pv-magazine) show that most connector failures can be traced back to poor installation, contamination, or environmental stress.

Installing M16 circular connectors correctly is essential to guarantee long-term reliability and safety in demanding applications. Field studies and technical research (Arrow, Keyence, pv-magazine) show that most connector failures can be traced back to poor installation, contamination, or environmental stress.

At Connoder, we specialize in designing and manufacturing high-performance circular connectors that meet the strictest industrial and outdoor requirements. Our About Us page explains our dedication to innovation, quality, and customer service — values that shape how we support you in achieving reliable system performance.

Common Causes of Connector Failures

Loose or improperly tightened locking nuts

Contamination and corrosion

Improper cable preparation

Excessive bending radius and mechanical strain

Thermal and electrical stress

From pv-magazine USA: field tests showed frequent failures due to tight cable bends, dirt inside connectors, and loose locking nuts.

From Keyence: microscopic analysis revealed oxidation, solder/crimp defects, and metal migration as key failure factors.

Proven Solutions & Preventive Measures

Use torque wrench to ensure locking nuts are properly tightened

Clean all contacts before assembly, keep seals in place

Respect cable bend radius and apply strain relief

Use correct wire stripping length, soldering or crimping tools

Match current rating and connector spec to operating conditions

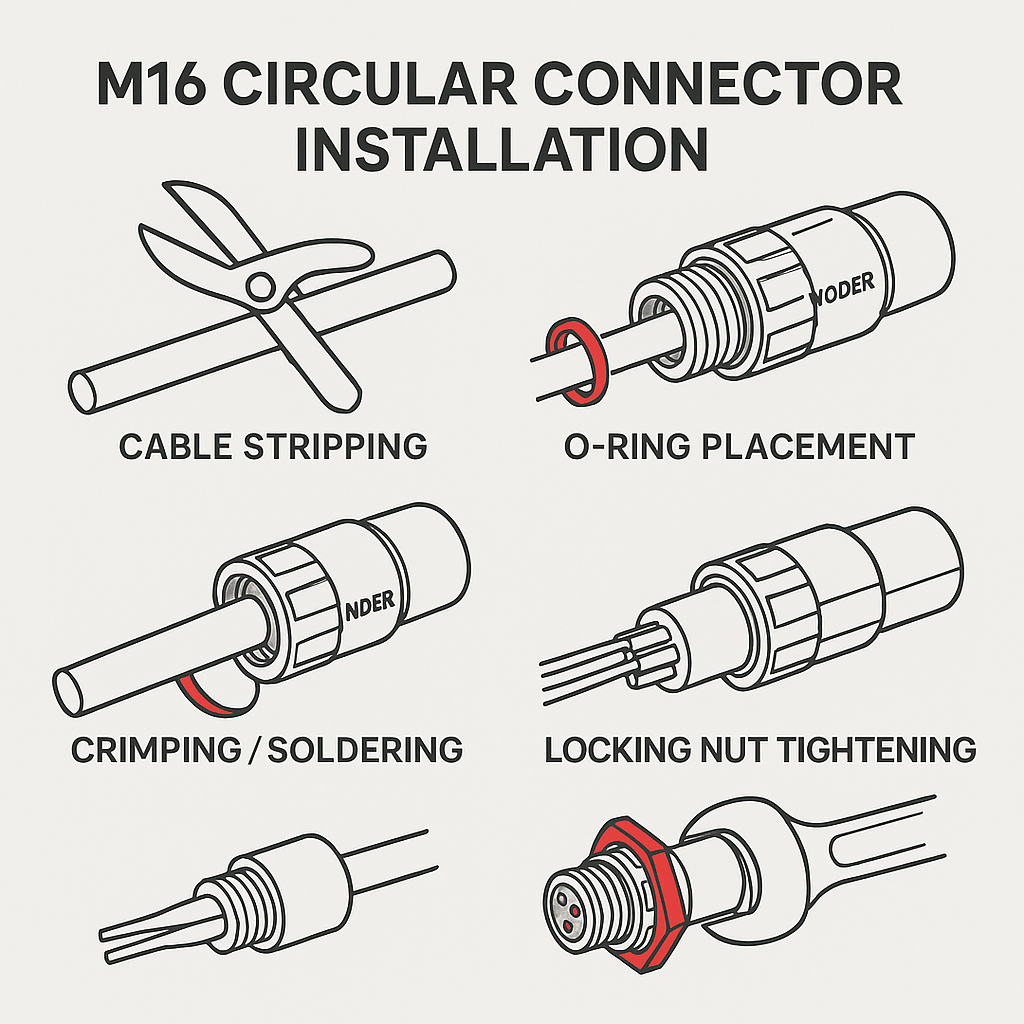

Step-by-Step: M16 Circular Connector Installation

Select the right connector variant

Prepare tools & materials

Strip cable insulation

Insert sealing components

Attach conductors via crimp/solder

Assemble housing and tighten with torque wrench

Test & inspect

Installation Diagram

Why Choose Connoder for M16 Circular Connectors

High durability: corrosion-resistant materials and precision engineering

Waterproof and rugged: IP67/IP68 rated models for outdoor, marine, and industrial use

Technical expertise: decades of connector design & application experience

Customer support: detailed datasheets, installation manuals, and service guidance

Product Showcase

Sample Content

Conclusion

Connector failures are often preventable with the right knowledge and the right products. By understanding common failure causes and applying best practices for M16 circular connector installation, you ensure system performance, reduce downtime, and increase safety.

Partner with Connoder to secure not just a connector, but a reliable long-term solution. Visit our About Us page to learn more about our commitment to quality and innovation.

M16 6 Pin Circular Connector A-Code Interface, Waterproof Connector Receptacle Cable, Straight, Front-Locking, Unshielded

M16 6 Pin Circular Connector assemblies are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems.

M16 6 Pin Circular Connector are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems. M16 Cable Connector are available in quick-lock wiring assembly types with IP67 protection and a vibration-resistant screw design.

M16 6 Pin Circular Connector are ideal for demanding industrial applications such as industrial automation and aerospace, marine, and telecom systems. M16 Round Female Connector are available in quick-lock wiring assembly types with IP67 protection and a vibration-resistant screw design.